ANALOG meets DIGITAL

Personalizing the design without compromising on the tactile effects

Handmade, exciting with a strong character. Craft beer finds its origin in backyard breweries in the USA, but its philosophy has since spread across the entire globe. It’s development takes place within a great number of high quality regional products, which are witnessing an increase in demand, due to the eco-friendly necessities of today’s consumers. This results in manufacturer’s increased requirement for higher quality packaging. An improvement of digital print or metallic finish through flatbed embossing can generate a visual and haptic experience, which is otherwise only found on luxury products. The implication is even possible in a cost-effective manner for small batches.

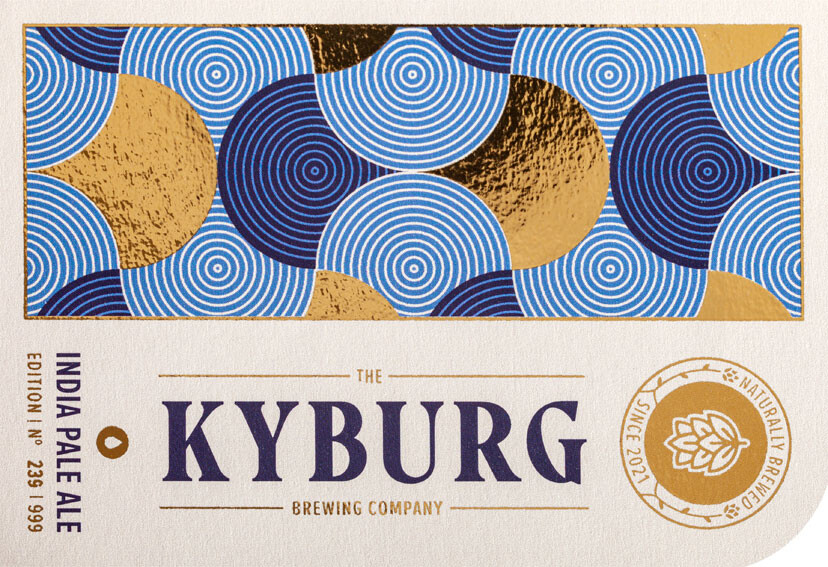

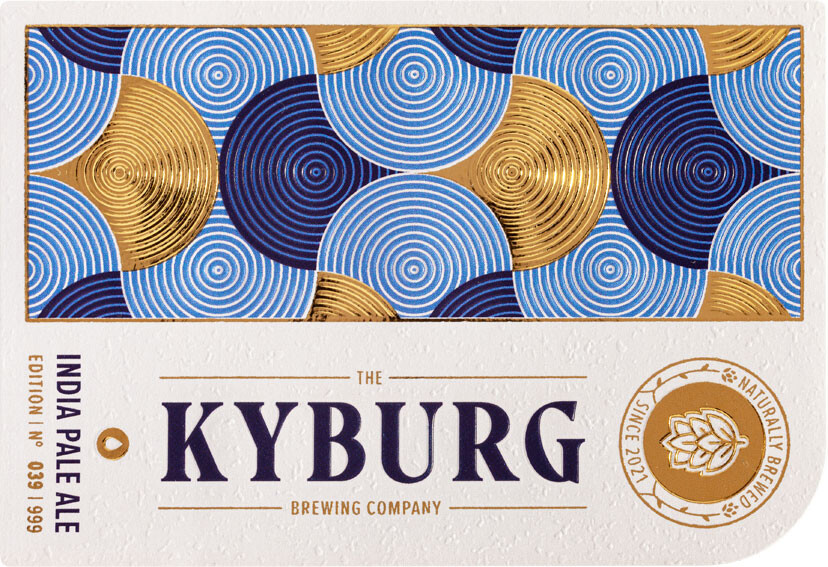

With the objective of meeting the requirements for haptic embellishment, the tool manufacturer H+M, the designer Zweischneider, the foil specialist Kurz, the printing company All4Labels and Pantec have cooperated and created the production example “Kyburg Craft Beer” to demonstrate the possibilities.

Patterns and tactile effects enhance digitally applied components in a unique manner

In the area of small batch package and label production, digital applications are usually the first choice. With digital printing, the quality is on a par with classic printing processes; digital metallization also already delivers shiny results. Applying haptic effects is currently outside of the capabilities of digital solutions. Hard edges, various embossing shapes and nano-/micro-embossing can only be achieved through analog application methods.

„Kyburg Craft Beer“ is a sample for high quality product packaging, used in small batches. The digital components and metallic effects are transformed into brilliant effects through analog blind embossing.

Gone are the days of “digital vs. analog”, where both technologies would compete against each other. Obviously it’s possible to work together -“Analog meets digital” is the name of the game. Here both technologies can benefit from each other’s advantages to guarantee the product’s recognition.

Analog meets digital: With the analog application of haptic effects as well as nano and micro embossing in the blind embossing process, both the digital metallization and the substrate are being enhanced

Kyburg Craft Beer:

The manufacturing steps

Six different motifs - a total of 6,000 labels - were produced for the "Kyburg Craft Beer" sample. In the first step, the metallic effect is applied to the blank substrate using a digital transfer solution. In the second step, the colours are applied by digital printing. In the third step, the label is refined with haptic and visual effects by using the flatbed embosser. At the end of the line, the labels are die-cut and weeded.

Step 1 - Applying the metallic effects

Step 2: Printing the colors

Step 3: Embossing of haptic effects and nano/micro patterns

Supplementary embossing offers numerous embellishment possibilities

Haptics is considered the first sensory channel, researchers describe it as a sense of truth with which whatever that is seen can be verified. Haptic effects are particularly appealing to consumers - an invitation to touch and grasp. These are the best possible complements to visual effects, and together they create an eye-catching, individual brand design.

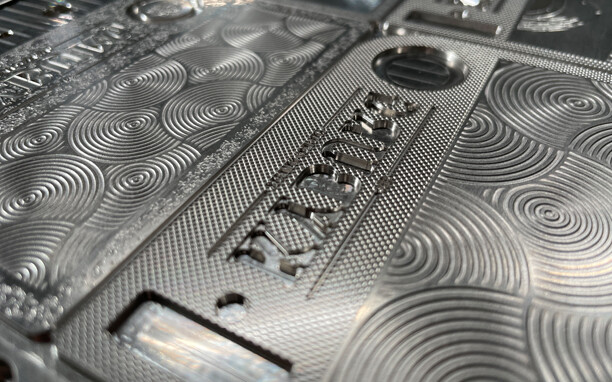

Embossing tools allow an optical improvement of designs with the addition of haptic elements.

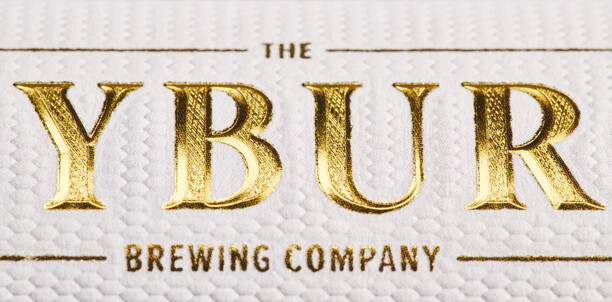

The "Kyburg Craft Beer" labels show the multitude of possibilities in the combination of digital and analog processes; nano-/micro-embossing as well as relief embossing transform the coloured and golden surfaces into a landscape of light, refractions, shadows, perceptible grooves and edges. Finally, a texturing blind embossing of the background gives the label material the appearance of structured paper and thus enhances its value. This is done with the embossing quality of the RHINO® and the precise embossing tools from H+M - which transform the labels into real eye-catchers.

Additional 3D embossing of metallized or printed elements

Both printed and metallic elements can be supplemented with a high-end relief by means of embossing. Therefore the substrate is shaped tri-dimensionally in the pre-printed or metallic areas.

Subsequent NanoEmbossing of metallized elements

With micro and nano embossing, very fine patterns are worked into the stamping die. This distorts the metallised surface of the substrate and creates impressive, optical reflection effects. Both an eye-catcher and difficult to copy at the same time.

Structuring of the substrate

With the right parameters, blind embossing can be used to apply the substrate with an individual structure. This allows unique surfaces to be implemented on basic substrates.

"It is advisable to focus on central elements in the embellishment design, such as the logo. Then the required embossing tools can permanently remain in the machine. A logo provided with micro embossing can thus become a trademark with a high recognition value."

Berat Abazi

Project Engineer | Pantec GS Systems AG

Efficient flat embossing system - success factor for short runs

In the field of high-quality embellishment of labels and packaging, foil embossing applied through a hot stamping process is the undisputed number one. This is solidified by precise embossed edges, impressive relief depths and pronounced gloss.

The only disadvantage of this process is that when changing jobs, not only the embossing tools but also the foils have to be swapped out. This is not a problem with medium runs, but with short runs, as in the case of regional products, the downtime for changing the foils and the embossing tool becomes the decisive factor for economic implementation.

The solution: the metallisation is applied by the digital process and the tactile effects by an embossing tool. This means that only the embossing tool needs to be changed on the embossing machine, which can be done quickly with a quick-change system like on the Pantec RHINO®.

In addition, the investment in the flat embossing system is considerably lower because the machine - as in the case of the Pantec RHINO® - can be purchased without a foil attachment.

By supplementing printed or metallised elements with embossing, extraordinary visual and haptic effects can be achieved.

Intelligent design concepts and flexible embossing tools ensure cost-effectiveness

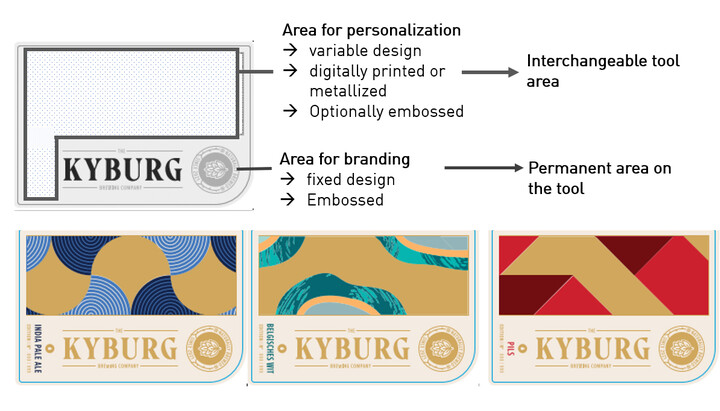

A central cost factor in flatbed embossing is the embossing tool. With variable small jobs, however, it does not necessarily mean that a separate embossing tool is needed for each job. On the contrary: a smart design concept makes it possible to implement the majority of jobs on the basis of one main tool. If new personalizations are to be refined, this can simply be added to the existing embossing tool.

Example of the optimisation of the design for the cost-effective layout of the embossing tool:

The design is divided into two areas. In the branding area, the logo and the visuals are always embossed in relief. This embossing tool part can always be used. For embossing in the personalised area, inserts can be used in the embossing die. This has a positive effect on set-up times and costs.

"The demand for embellishment is still high, it’s even increasing. But it’s changing. We are currently observing a development away from classic hot embossing towards transfer finishing with additional blind embossing. We’re working solely with the deformation of the paper and can thus create a variety of impressions that can be precisely matched to the respective brand design."

Thomas Löchner

Creative Manager | Hinderer + Mühlich GmbH & Co. KG

The appropriate flatbed system for short runs

From a production technology point of view, two factors are essentially decisive for the selection of a suitable flatbed system. On the one hand, the demands on the embossing quality are extremely high so that effects such as 3D embossing or micro/nano structures can be realised. On the other hand, a quick changeover of the machine must guarantee productive operation. With the RHINO® E, Pantec offers a perfectly tailored embossing system that can be integrated into any converting system.

Impressions of the production of the Kyburg Craft Beer label

Kick short runs up a notch with tactile effects!

Short-run embellishment gives you a unique opportunity to offer your customers unique packaging solutions in the high-value, regional products segment.

Take the next step now!

You want to see the stunning look of an analog enhanced digital packaging?

You want to talk about your design ideas?